+33 (0) 02 99 91 03 01

The durable anti-slip !

MGS Industries Technology

MGS Industries manufactures non-slip sheets

The durable anti-skid

In all extreme cases of use : outdoor, indoor, high temperature industrial environments, public places, esplanades, public facilities, transport, metro, port environments, oil platforms …

The Agrain® sheet meets all slippery environment problems : greases, hydrocarbons, inclined planes, bad weather …

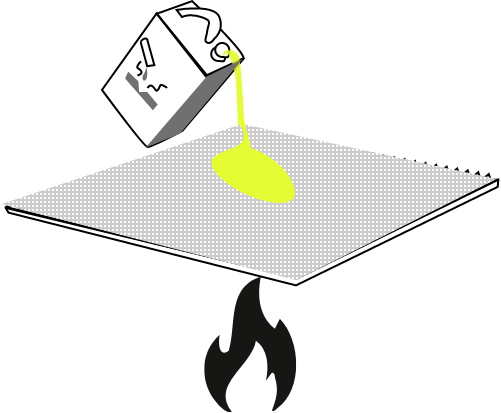

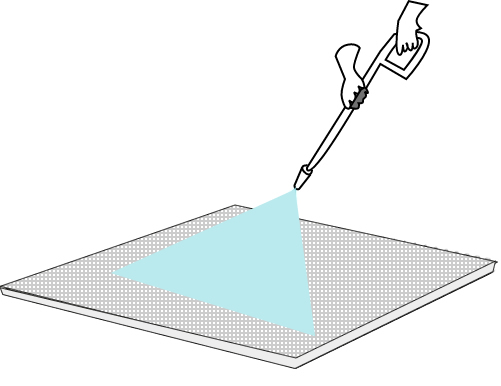

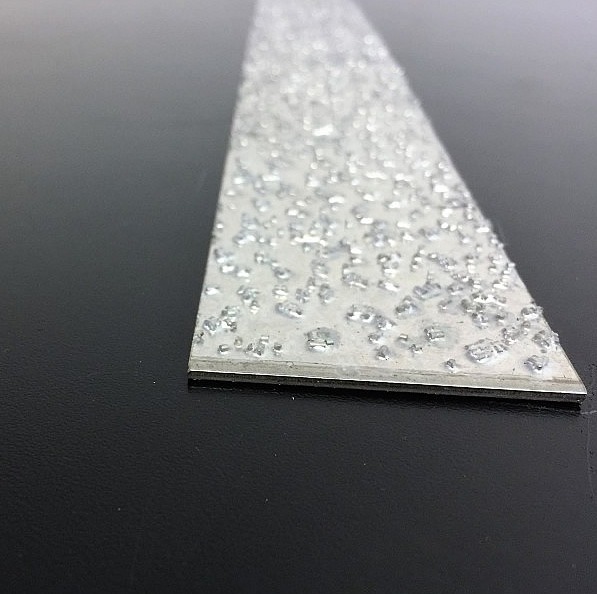

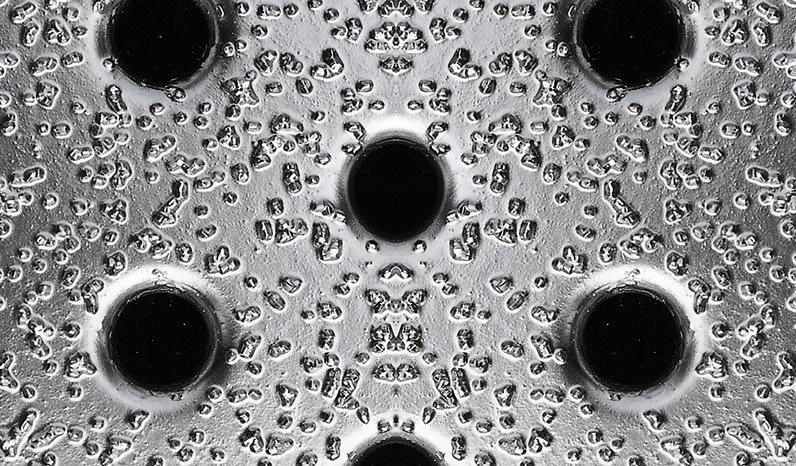

Agrain®, an innovative process

Projection of metal pellets on a substrate previously coated with a tin-based binder, then passed through a high-temperature furnace where welding is performed by Thermofusion.

The Agrain® advantages

Resistant to all detergents

Reduced fouling due to particle spacing

Highly effective anti-slip for extreme cases

Easy cleaning even with high pressure washer

MGS Industries

For nearly thirty years, MGS Industries has been manufacturing non-slip products for industry and public spaces. Agrain® sheet reduces and eliminates the risk of slipping in the workplace and in public places. Used to facilitate access for people with reduced mobility, the Agrain® sheet can be adapted to any type of environment.

MGS Industries means

The MGS Industries company has dynamic human resources and high quality material to match its projects. All these material and human resources allow us to offer a wide range of quality products with respect to deadlines.

Photo of the MGS Industries team taken in La Gacilly by Yann Arthus-Bertrand, October 2024 – www.yabstudio.fr«

Key numbers

1600 m² Of workshop surface

3 Production lines

10 000 m² Of non-slip plates / year

160 m² of Office space

Services

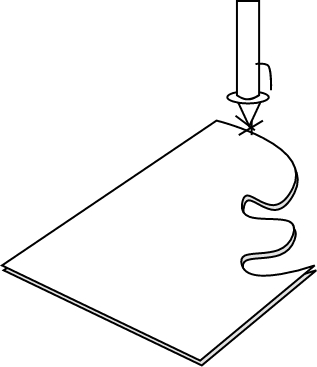

Laser cutting

laser cutting center Laser LVD Axel 2.5 kw 1500×3000.

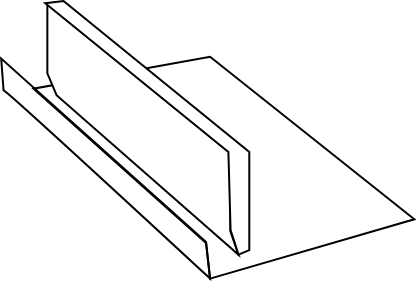

Bending

With our LVD PPS 200/30 press brake, we meet your requirements for all types of bending.

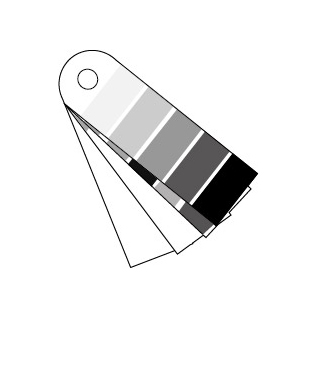

Colors & Patterns

On request: powder coating in the RAL color of your choice, with the option of patterns such as stripes, chevrons, etc.

Design Office

We work with you to assess the technical feasibility of your project, in order to best meet your requirements and support you in its successful completion.

The equipment

Our references

Metal sheet Agrain® galva® & Grepon®

Support

Material up to 4mm : Galva DX51+Z275 Material up to 6mm : Acier DKP

Angular particles

Cast iron

INRS test report

IET/09RI-270/HS

Binder

Tin base

Hardness

60 HRC

Friction Coefficient

0,67 Чd

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium

Slope

30%

Resistance

170°

Grain

G55, G47, G34, G24, G17, G07

Composition

Galva

Technical characteristics

| Code | Support | Thickness | Dimensions |

|---|---|---|---|

| 1000 | Galva DX51+Z275 | 0,6mm | 1000 x 2000 | 1250 x 2500 |

| 1001 | Galva DX51+Z275 | 1mm | 1000 x 2000 | 1250 x 2500 |

| 1002 | Galva DX51+Z275 | 1,5mm | 1000 x 2000 | 1250 x 2500 |

| 1003 | Galva DX51+Z275 | 2mm | 1000 x 2000 | 1250 x 2500 |

| 1004 | Galva DX51+Z275 | 3mm | 1000 x 2000 | 1250 x 2500 |

| 1005 | Galva DX51+Z275 | 4mm | 1000 x 2000 | 1250 x 2500 |

| 1006 | DKP | 5mm | 1000 x 2000 | 1250 x 2500 |

| 1007 | DKP | 6mm | 1000 x 2000 | 1250 x 2500 |

Main Applications

Industrial floors, Factories, Workshops, Platforms, Work Podiums, Inclined planes, Access ramps, Footbridges, Stairs, Vehicle Steps, Access for reduced mobility people, Emergency staircases,

Inox metal sheet

Support

Stainless steel 304L

Stainless steel 316L (optional)

Angular particles

Stainless steel

INRS test report

IET/09RI-270/HS

Binder

Tin base

Hardness

60 HRC

Friction Coefficient

0,59 Чd

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium

Slope

30%

Resistance

170°

Grain

CR100, CR80, CR60, CR40

Composition

Stainless steel

Technical characteristics

| Code | Thickness | Dimensions |

|---|---|---|

| 2001 | 0,8mm | 1000 x 2000 / 1250 x 2500 |

| 2002 | 1,5mm | 1000 x 2000 / 1250 x 2500 |

| 2003 | 2mm | 1000 x 2000 / 1250 x 2500 |

| 2004 | 3mm | 1000 x 2000 / 1250 x 2500 |

| 2005 | 4mm | 1000 x 2000 / 1250 x 2500 |

| 2006 | 5mm | 1000 x 2000 / 1250 x 2500 |

| 2007 | 6mm | 1000 x 2000 / 1250 x 2500 |

Main Applications

Industrial floors, Factories, Workshops, Platforms, Work Podiums, Inclined planes, Access ramps, Footbridges, Stairs, Vehicle Steps, Access for reduced mobility people, Emergency staircases,

Agrain® Dur metal sheet & Grepdur® metal sheet

Material

DKP DD11

Angular particles

Cast iron

Tungsten Carbide (optional)

INRS test report

IET/09RI-270/HS

Binder

Copper base

Hardness

60 HRC

Friction Coefficient

0,78 Чd

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium

Slope

30%

Resistance

Up to 1000°

Grain

G55, G47, G34, G24, G17, G07

Composition

Cast iron

Technical characteristics

| Code | Angular particles | Thickness | Dimensions |

|---|---|---|---|

| 5001 | Cast iron | 1mm | 500 x 2000 |

| 5002 | Cast iron | 1,5mm | 500 x 2000 |

| 5003 | Cast iron | 2mm | 500 x 2000 |

| 5004 | Cast iron | 3mm | 500 x 2000 |

| 5005 | Cast iron | 4mm | 500 x 2000 |

| 5006 | Cast iron | 5mm | 500 x 2000 |

| 5001 A | Tungsten | 1mm | 500 x 2000 |

| 5002 A | Tungsten | 1,5mm | 500 x 2000 |

| 5003 A | Tungsten | 2mm | 500 x 2000 |

| 5004 A | Tungsten | 3mm | 500 x 2000 |

| 5005 A | Tungsten | 4mm | 500 x 2000 |

| 5006 A | Tungstène | 5mm | 500 x 2000 |

Main Applications

Inclined planes for passing, Heavy trucks Working podiums with risk of throwing, Metal or molten glass Roller clips

(cardboard, stationery, etc.), Drive Rollers (transfer) Around machining machines

(projection of chips or soluble oil) Unloading docks (handling) etc …

Tape Profile by Agrain ®

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium and corrosive medium

Resistance

170°

Grain

G55, G47, G34, G24, G17, G07 ou CR100, CR80, CR60, CR40

Composition

Stainless steel, galva or DKP

Technical characteristics

| Code | Composition | Welding | Angular particles | Thickness | Dimensions | Grains |

|---|---|---|---|---|---|---|

| 100013 | Galva | Tin | Cast iron | 0.6mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 100113 | Galva | Tin | Cast iron | 1mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 100213 | Galva | Tin | Cast iron | 1.5mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 100313 | Galva | Tin | Cast iron | 2mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 100413 | Galva | Tin | Cast iron | 3mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 500013 | DKP | Copper | Cast iron | 0.8mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 500113 | DKP | Copper | Cast iron | 1mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 500213 | DKP | Copper | Cast iron | 1.5mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 500313 | DKP | Copper | Cast iron | 2mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 500413 | DKP | Copper | Cast iron | 3mm | 50x2000mm | G55, G47, G34, G24, G17 ou G07 |

| 200113 | Inox | Tin | Stainless steel | 0.8mm | 50x2000mm | CR100, CR80, CR60 ou CR40 |

| 200213 | Inox | Tin | Stainless steel | 1.5mm | 50x2000mm | CR100, CR80, CR60 ou CR40 |

| 200313 | Inox | Tin | Stainless steel | 2mm | 50x2000mm | CR100, CR80, CR60 ou CR40 |

| 200413 | Inox | Tin | Stainless steel | 3mm | 50x2000mm | CR100, CR80, CR60 ou CR40 |

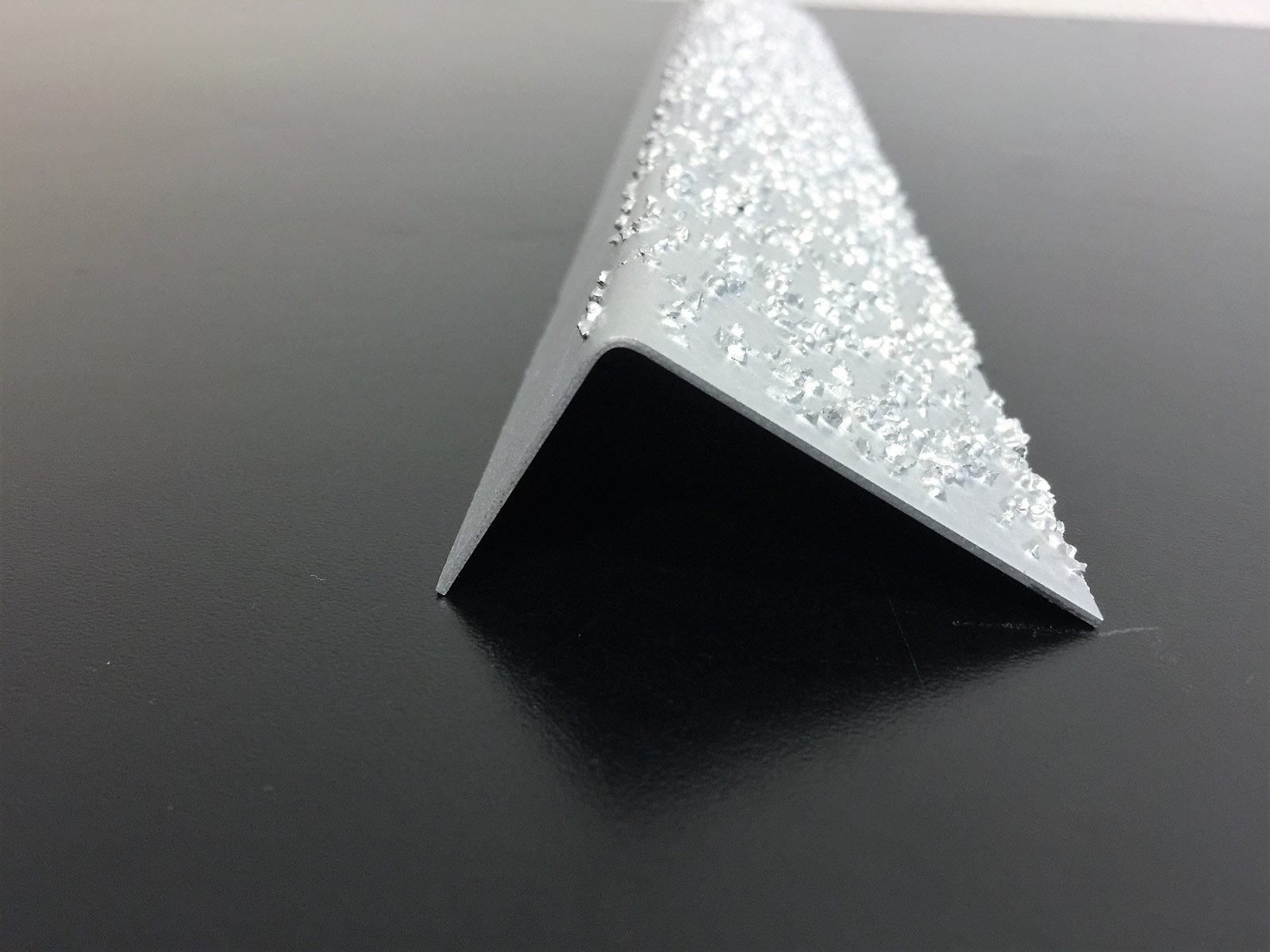

Corners by Agrain ®

On request: RAL painted paint of your choice

Standard size

Length: 2000mm

Depth: 50mm

Falling edge: 30mm

Technical characteristics

| Article reference | Angular particles | Sheet metal thickness |

|---|---|---|

Galvanized steel |

||

| 6001 | Cast iron | 1mm |

| 6002 | Cast iron | 1,5mm |

| 6003 | Cast iron | 2mm |

Stainless steel 304L |

||

| 6005 | Stainless steel | 0,8mm |

| 6006 | Stainless steel | 1,5mm |

| 6007 | Stainless steel | 2mm |

Gratings by Agrain ®

Anti-slip elements

Cast iron or stainless steel angular particles

Binder

Tin base

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium

Slope

30%

Resistance

160°

Grain

G55, G47, G34, G24, G17, G07

Composition

Cast iron

Technical characteristics

| Code | Thickness | Dimensions |

|---|---|---|

| 2001 | 0,8mm | 1000 x 2000 / 1250 x 2500 |

| 2002 | 1,5mm | 1000 x 2000 / 1250 x 2500 |

| 2003 | 2mm | 1000 x 2000 / 1250 x 2500 |

| 2004 | 3mm | 1000 x 2000 / 1250 x 2500 |

| 2005 | 4mm | 1000 x 2000 / 1250 x 2500 |

| 2006 | 5mm | 1000 x 2000 / 1250 x 2500 |

| 2007 | 6mm | 1000 x 2000 / 1250 x 2500 |

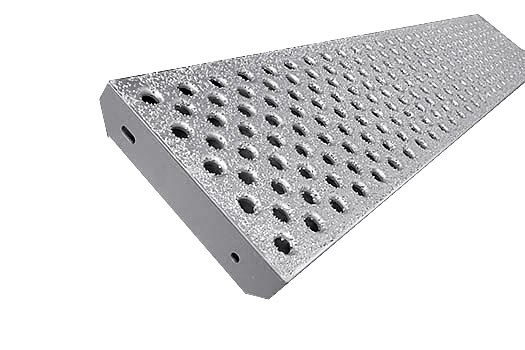

Steps by Agrain ®

Anti-slip elements

Cast iron angular particles hardness 60 H.R.C.

Binder

Tin base

On request: RAL painted paint of your choice

Laying

Interior Exterior Low-corrosive medium

Slope

30%

Resistance

160°

Grain

G55, G47, G34, G24, G17, G07

Composition

Cast iron

Technical characteristics

| Code | Flange | Depth | Width | Height | Flanks |

|---|---|---|---|---|---|

Standard stand-up step |

|||||

| 4001 | 15mm | 240mm | 500mm | 35mm | 3mm |

| 4002 | 15mm | 240mm | 600mm | 35mm | 3mm |

| 4003 | 15mm | 240mm | 700mm | 35mm | 3mm |

| 4004 | 15mm | 240mm | 800mm | 35mm | 3mm |

| 4005 | 15mm | 240mm | 1000mm | 35mm | 3mm |

Perforated sheet metal |

|||||

| 4006 | 15mm | 240mm | 500mm | 35mm | 3mm |

| 4007 | 15mm | 240mm | 600mm | 35mm | 3mm |

| 4008 | 15mm | 240mm | 700mm | 35mm | 3mm |

| 4009 | 15mm | 240mm | 800mm | 35mm | 3mm |

| 40010 | 15mm | 240mm | 1000mm | 35mm | 3mm |

Main Applications

Industrial floors, Factories, Workshops, Platforms, Work Podiums, Inclined planes, Access ramps, Footbridges, Stairs, Vehicle Steps, Access for reduced mobility people, Emergency staircases,

Agrain® Discs

Anti-slip elements

Cast iron angular particles hardness 60 H.R.C.

Binder

Tin base

AGRAIN® tungsten carbide abrasive discs (the hardest material after diamond) are essential tools for polishing, deburring, surface preparation, and sanding operations. They offer a wide range of applications on various materials such as steel, wood, cement, plaster, soft stone, aerated concrete, paint, varnish, plastic, rubber, cork, leather, sandstone, fiberglass, and even animal hooves. Thanks to their tungsten carbide coating, AGRAIN® discs provide extended durability.

Types of Machines: Cut-off or Grinding Machines (maximum speed 10,000 rpm)

Steel Type: DKP DD11

Disc Thickness: 3 mm

Abrasive Type: Tungsten Carbide

Bore Diameter: Standard Ø 22 mm

Grit Size: 14 (2000µm–1200µm), 24

(1600µm–800µm), 36 (1000µm–500µm)

Brazing: Copper

Main Applications

- Optimal for stripping beams or removing

concrete residues on formwork boards - Ideal for the removal of protective coatings

or residues of glue before laying tiles - Effective to remove thick paint layers

or equalize fiberglass plastics - To work the soft stone or to make roundings

and chamfers on the marble - To easily and accurately grind

cellular concrete or plaster tiles - For the animal clogs maintenance

You have a projet

Address :

Parc d’Activités du Pays de Grand Fougeray

Espace Nord

11 Rue des Pionniers

35390 GRAND-FOUGERAY

FRANCE

Phone :

33 (0)2 99 91 03 01

E-mail :

mgs-industries@orange.fr

Legal Notice

Publishing Director

MGS Industries

Parc d’Activités des 4 Routes

35390 GRAND-FOUGERAY

FRANCE

Phone: +33 (0)2 99 91 03 01

Fax: +33 (0)2 99 91 06 42

Email: mgs-industries@orange.fr